Cintec Anchors

Old, historic and listed buildings and

monuments often require structural repairs, having deteriorated

over time. Traditionally pattress type plates and tie

bars were used to stabilise these structures, and repair the

cracks in the walls. However, these solutions are not always

the most aesthetically pleasing.

Old, historic and listed buildings and

monuments often require structural repairs, having deteriorated

over time. Traditionally pattress type plates and tie

bars were used to stabilise these structures, and repair the

cracks in the walls. However, these solutions are not always

the most aesthetically pleasing.

Cintec anchors are much more suitable for the restoration of

historic and heritage buildings, as they are less obtrusive

aesthetically than conventional tie bars and pattress plates.

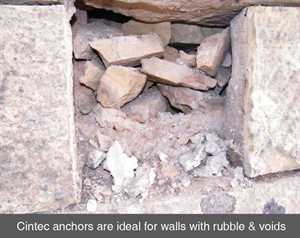

Cintec Anchors are especially suited for the repair of

cracks in rubble filled or voided stone walls.

Stronghold Preservation are Cintec anchors approved

installers.

How Cintec Anchors Work

The Cintec anchor system comprises of a steel bar (or

multi-bars) enclosed in an elasticated porous fabric sleeve.

Holes are diamond drilled into the masonry or stone, into which the

anchors are placed. The grout is pressure injected under

controlled low pressure, which fills through a grout tube from the

rear to the front, until the sock is entirely filled.

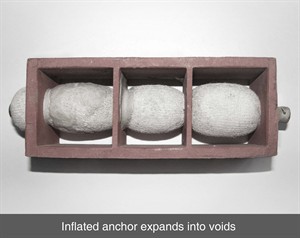

Cintec Sock

The elasticated Cintec sock serves several functions; It

initially acts as a formwork for the high strength grout, allowing

it to expand tightly into the drilled hole. It will aslo expand a

further 30-50% more than the drill hole size, which allows the

grout to expand into the natural voids and contours of the wall.

This expansion into the voids provides a strong mechanical fixing

within the structure, along the entire length of the

anchor. This can reduce the requirement for any unsightly

pattress plates on the exterior of the structure, as the anchor is

bonding along it's length rather than having a point load at the

end plates.

The elasticated fabric sock allows most of the water content of

the cementitious grout (Grout milk) to pass through, whilst

leaving the concentrated, dense, non-shrink solids within the

sock.

Additionally, by allowing the 'grout milk' to pass through the

fabric sock it creates a chemical bond with the substrate in

contact with the anchor.

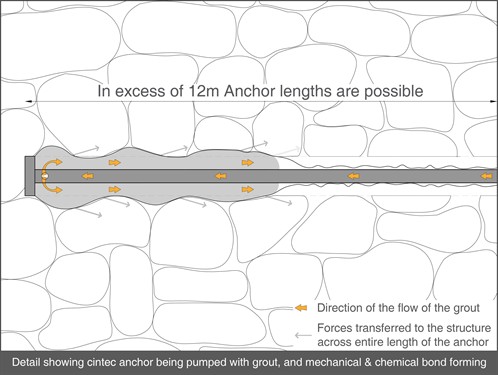

Inflated Cintec Anchor Detail

The grout is injected through a circular hollow section bar or

plastic grout tube. This allows the anchor to be pumped from one

end, filling the sock up from the rear. This process of grouting

from the rear to the front provides a high degree of quality

control, as the final part to inflate is at the front.

The grout is injected under pressure which expands the

elasticated Cintec Sock Anchor into natural voids within the wall,

creating a mechanical and chemical bond within the wall

The load is imparted more evenly than traditional anchors, due

to the bond created by the expansion into the natural voids over

the full length of the anchor.

Quality Control

The installation process for the Cintec anchor system

automatically provides the user with a high degree of quality

control. As most anchor holes are 'blind' ie the operative cannot

see the far end, there is a risk, with other systems, that the

furthest end may not be correctly filled or surrounded in grout.

With the Cintec Anchor system, the sock will not inflate at the

front (visible end) until the remainder of the anchor has filled

with grout, therefore the installer can ensure that the entire

anchor is fully grouted. As a licensed Cintec Approved Installer,

Stronghold Preservation have been trained in these techniques.

Specialist Drilling

As the Cintec anchors are often installed in historic buildings

that are unstable, the drilling system msut be sympathetic to the

structure and avoid causing further damage. Specialist diamond

drilling techniques are used to drill long holes, which can be in

excess of 12m. The diamond drilling system creates little vibration

and is extremely accurate over long distances, making it ideal for

historic buildings and structures.

Often when there are structural problems in historic buildings,

the walls are voided or rubble filled, making any drilling

difficult, due to the fact that the loose core often collapses into

the drill hole after the drill bit is removed, making the insertion

of the anchor difficult if not impossible. Special hollow,

extendable diamond cores are used to keep the drill hole open and

prevent the hole closing in, allowing the Cintec Anchor to be

inserted.

Advantages of Cintec Anchors

- Ideal for void filled or loose rubble filled walls

- Capable of being installed in long anchor lengths - Up to 30m

Cintec anchors have been installed

- Effective high strength anchors are possible in poor quality,

soft masonry

- Ideal for bridging cavities, without grout loss

- Good quality control in long 'blind' holes - Sock inflation at

front provides proof that the entire anchor is surrounded by

grout

- Sympathetic with existing structures - Cintec uses natural

cementitious, non-resin grouts

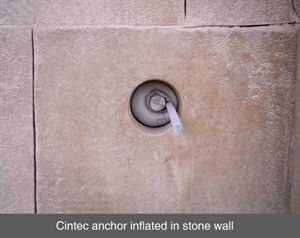

- Minimal visibility when installed - No pattress plates

necessary

- Resistant to fire compared to resin fixings

- Approved by heritage organisations

Applications for Cintec Anchors

The Cintec Anchors are suitable for use in:

- Structural repairs, including corner cracks, brick arch

failure, bridges etc.

- Stabilisation of unstable structures

- Conservation: Cintec anchors are sympathetic to the building

fabric, and are suitable for the restoration of heritage buildings,

especially void filled walls.

- Strengthening the load bearing capacity of structures

- Long Anchor Lengths: Cintec anchors have been installed up to

30metres long

- Cintec anchors provide a discreet finish, and are therefore

particularly suitable to areas where high aesthetic control is

required, eg listed and heritage buildings.